AILESEN (CHANGZHOU)

Professional qualifications, Create a boutique, Excellent quality, Trust the price.-

The price is

transparent -

Advanced

concepts -

Diamond

quality -

outstanding

productivity -

Process

monitoring -

Personalized

service

The advantages of AILESEN

Professional qualifications, to create quality, excellent quality, trust in price.The application case

Professional qualifications, to create quality, excellent quali-

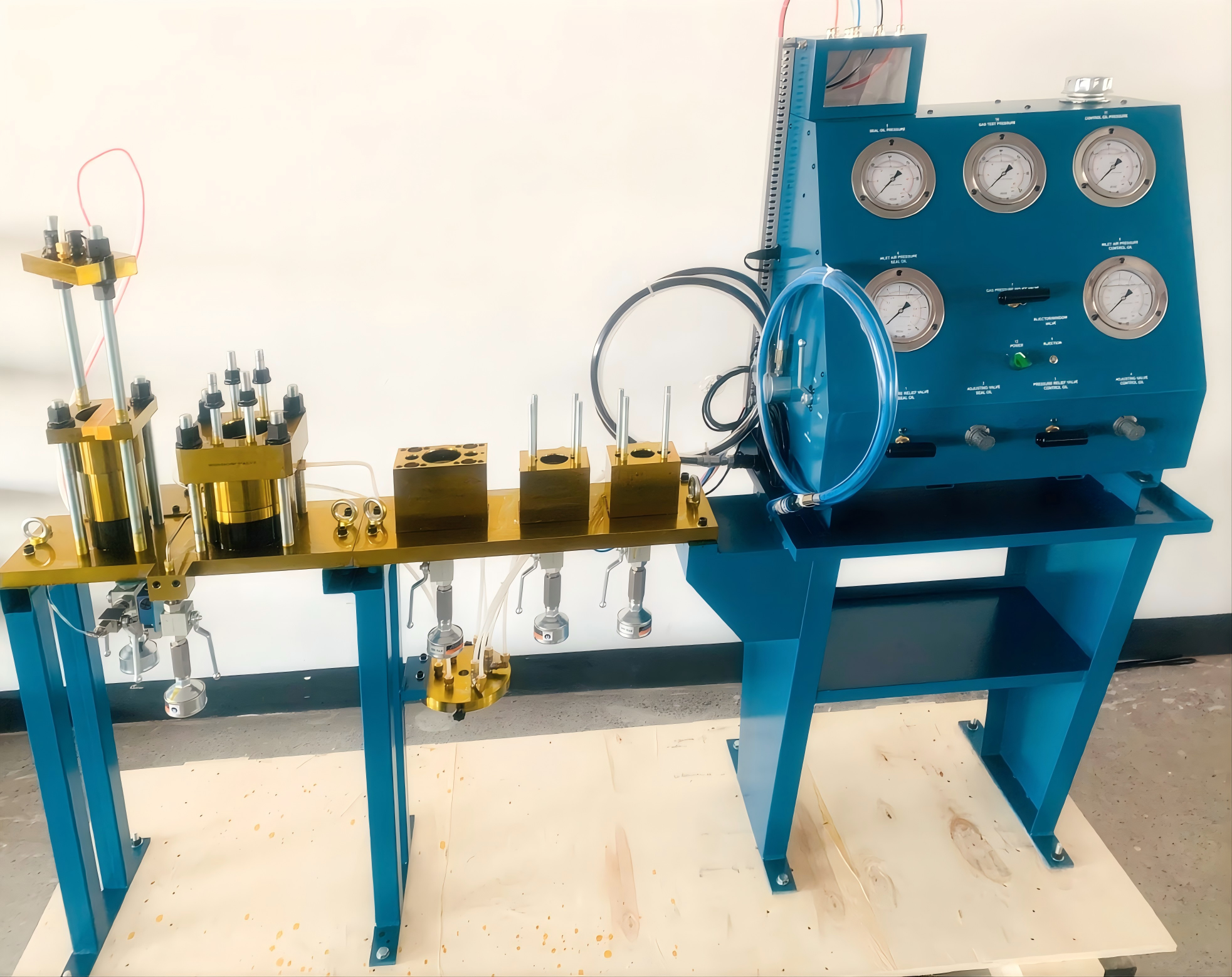

Gas Fuel Injector Test Unit / VPU 500 GI

Gas Fuel Injector Test Unit / VPU 500 GIEngine Type:ME-GIThe VPU 500 GI is a gas-powered gas valve test rig suitable for testing gas fuel injectors on two-stroke engines.This test rig is suitable for MAN GI engines.The VPU 500 GI is a pneumatic/hydraulic gas fuel injector test rig for GI engines. The VPU 500 GI gas fuel injector test rig features a robust design and is suitable for testing gas injectors, window valves, and pressure relief valves using 300 bar or 400 bar nitrogen. It features five stations for testing window valve seals, block valve seals, gas channel relief valve seals, bleed valve seals, and closed non-return valve seals.Features of VPU500-GI:Gas leak detection: detect gas leaks and detect if gas is leakingSimulated booster: provides the pressure required for test gas injectionSafety Valves and Sensors: Guarantees safe testing conditions by continuously monitoring system pressure and performance.09-102025

-

Hydraulic Jack

Hydraulic Jack Test of 2200 Bar Hydraulic JackApplicable engine type:S65ME-C, G70ME-C, K80ME-C, S80ME-C, G80ME-C, K90ME-C, S90ME-C, G95ME-C, K98ME-C, K98ME.1. Safety measures In case of malfunctioning hydraulic jacks or hoses 1.1 Always keep clear of area above the pressurized hydraulic jack during use. Broken studs or malfunctioning jack can eject! 1.2 Bursting hydraulic hose can eject oil into the skin! Always inspect the hose assembly before use. Defective or damaged hose assemblies must be replaced and discarded!1.3 Verify correct engagement of couplings before applying hydraulic pressure1.4 Leaking hydraulic oil can pose a risk in case of skin contact. Always use goggles and oil resistant gloves when working with hydraulic oil.08-142025

-

FUEL VALVE TEST DEVICE HDFD1100 COMMON FAULTS AND TROUBBLES HOOTING

FUEL VALVE TEST DEVICE COMMON FAULTS AND TROUBBLES HOOTING Model:HDFD11001. Unable to build pressure:1.1 Check whether the fixing screw nut of the fuel valve is tightened (tighten the nut).1.2. Check whether the test hydraulic oil meets the hydraulic oil specified in this manual (replace the specified oil).1.3. Check whether the hydraulic oil filter in the oil tank is cleaned at the specified time (replace and clean the oil filter).1.4. Check whether the oil level in the oil tank is too low (increase the test oil).2. The fuel valve test device does not work: 2.1. Check whether the air pipe connecting the device is unobstructed (replace the joint and air pipe). 2.2. Check whether there is air pressure in the air pressure regulating valve (3) and the input air meter (6) (replace the air pressure regulating valve). 3. Pressure leakage: 3.1. Check whether there is leakage at the joints inside the test bench (tighten the joints). 3.2. Check whether the return oil valve is leaking (grind the return oil valve stem, replace the return oil valve). 3.3. Check the high-pressure oil pump input and output connectors for oil return (disassemble and clean or replace both connectors).4. Pressure gauge does not return to zero at zero pressure:After the pressure on the test bench is completely released, adjust the "0-adj" knob on the rear of the digital display to zero.Turn clockwise to increase, counterclockwise to decrease. (If there is no response, replace the pressure gauge and pressure sensor).5. Digital display does not display:5.1. Check the digital display power input terminals (terminals 1 and 2 are 110VAC; terminals 1 and 3 are 220VAC. Consult the ship's electrical engineer to determine which input terminal to use based on the ship's conditions).5.2. Check the input terminals for power. If there is power but no display, replace the digital display.6. Digital display displays garbled data:If garbled data persists after replacing the pressure sensor, replace the digital display.08-082025

ESX

ESX

MS

MS

AHP1500

AHP1500

T8

T8

AHP2500

AHP2500

AHP3500

AHP3500

AHP3500.2

AHP3500.2

VTU-H001

VTU-H001

DH

DH